Basic Info.

Application

Vegetable, Fruit, Fish, Meat, Snack, Seasoning

Type

Forming Filling Sealing Machine

Forming Species

Bag Moulding

Forming Function

Forming, Filling, Seal

Driven Type

Electric

Material Type

Grain

Packaging

Bag

Packaging Material

Film

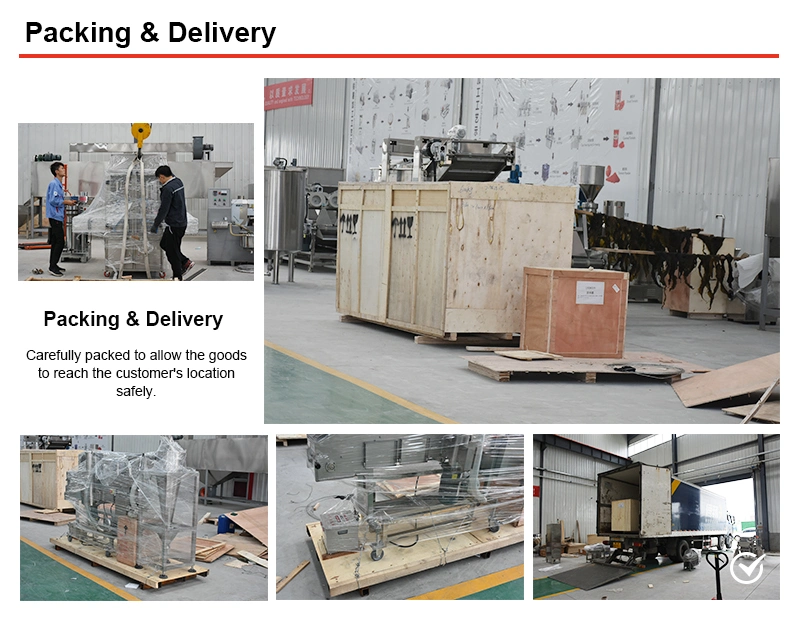

Transport Package

Standard Export Wood Pack

Specification

CE

Trademark

GELGOOG

Origin

China

Product Description

1. Application:

2. Soya Chunks Packing Machine Features

(1) Efficient: Bag - making, filling, sealing, cutting, heating, date/lot number achieved in one time;

(2) Intelligent: Packing speed and bag length can be set through the screen without part changes;

(3) Profession: Independent temperature controller with heat balance enables different packing materials;

(4) Characteristic: Automatic stop function, with safe operation and saving the film;

(5) Convenient: Low loss, labor saving, easy for operation and maintenance;

(6) Weighing accuracy 0.2 to 1.0 gram.

3. Soya Chunks Packing Machine Specification:

| Model | GG-LK420 |

| Film width | max 420mm |

| Bag width | 80-200mm |

| Bag length | 50-300mm |

| Packing speed | 15-80bags/min |

| Packing range | 150-1500ml |

| Film thickness | 0.04-0.10mm |

| Power | 2.5kw/220v 50-60Hz |

| Machine size | 1400*970*1700mm |

| Machine weight | 450kg |

| Air consumption | 0.4m³/min 0.6mpa |

4. Soya Chunks Packing Machine Details

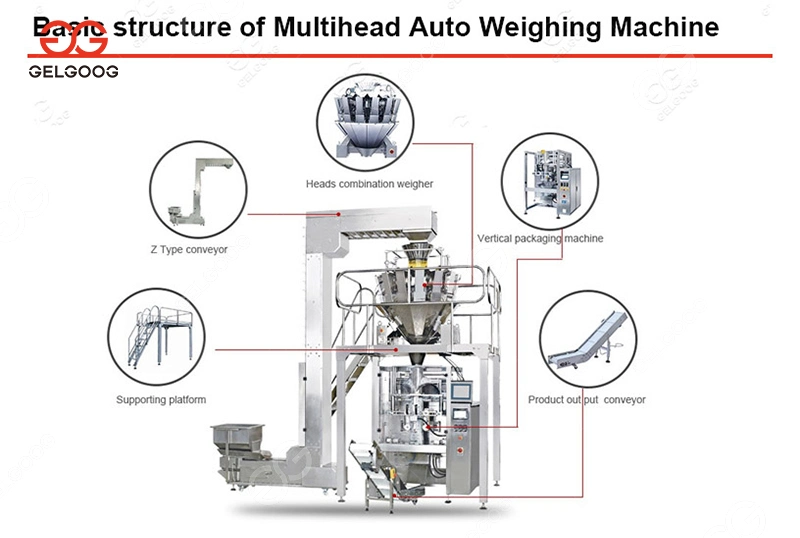

(1) Multi Heads Weigher

a) 4 -14 heads can be optional.

b) Weigher buckets have an independent control mode. When compared to the standard weigher speed increased by 10% and capable to perform a faster and more accurate calculation.

c) Sample collection function makes the weighing process more accurate.

d) New features include low supply warning, controllable feeding, automatic material filling and failure rejection functions.

(2) Packing Machine

Precision bag former & touch screen, digital screen display with numerical setting and flexible operation; Imported PLC control system and color touching screen, easy operation; PID independent control of temperature, more suitable for different packaging material.

(3) Z Type Elevator

a) The elevator and electronic metering scale is used together, the control circuit is used to control the material's position, realizing automatic feeding and stopping function.

b) The elevator can be made of stainless steel or carbon steel, according to the customer, choice.

c) The Bucket conveyor (Z-shaped) is designed to handle both tough and sanitary applications.

(4) Finished Product Conveyor

Adopting imported miniature motor and featured with low noise and long lifetime. It can transport finished goods to the platform, reduce waste during packing, making the machine work more smoothly. Greatly submitted production efficiency and reduced labor costs.

5. Packing and Shipping

Packaging: machinery standard packaging or customized. Shipping: By Air, by Sea or by Express (DHL, etc) Shipment cost will depend on the destination, shipment way and the weight of the goods.